In Q4 of 2020, final testing was launched as part of the process of obtaining European homologation for the SK080ES electric model. Completion of the homologation process is expected in Q1 2021. Our research and development team has been working in parallel since Q2 2020 on the development of the SK080HS hydrogen powered prototype model.

In addition to the development and configuration of a new hydrogen drive unit, this complex project also includes a change in the external and internal design and further improvement of the structural properties of the body.

By design, the bus is intended primarily for city traffic. Its modular body construction means that it can have a total of 3 variants of its design, in terms of the number of doors and seats. The body is self-supporting and made from composite materials that are not subject to corrosion - it has no welds or steel parts. In addition, it is very light, strong, non-conductive and non-flammable, easy to maintain and, if properly maintained, its service life can easily reach 40 years.

The produced hydrogen model has a total length of 7982 mm, a width of 2550 mm and a height of 2940 mm. A total of 68 passengers can be comfortably transported on board, of which 20 have a place to sit. The boarding platform is low-floor, thus offering barrier-free access for strollers, bicycles or disabled people in wheelchairs.

Adjustable and powerful air conditioning with a heat pump is standard. Its function is also assisted by an additional heat exchanger, with which the residual heat obtained during the conversion of hydrogen into electrical energy is recovered.

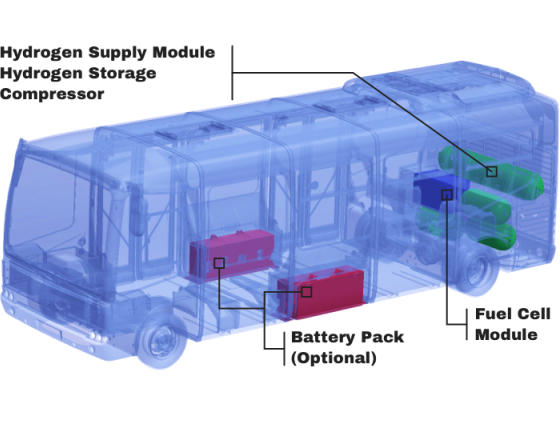

A Siemens Elfa electric motor with a total power of 160 kW and a torque of 2500 Nm was used to drive the bus. The electric motor is powered by a pair of accumulators with a total capacity of 70 kWh.

A bus powered in this way can travel up to 110 km purely on electric power. To increase the range up to 410 km, a highly efficient hydrogen fuel cell was integrated into the system, which charges both batteries while driving with a maximum of 30 kW. It obtains the energy for this through a chemical reaction of oxygen and hydrogen - it obtains oxygen from the surrounding air and hydrogen from equipped high-pressure tanks with a total capacity of 10.5 kg.

The hydrogen is stored in a total of 4 tanks under a pressure of 350 bars, uniquely in the traditional "rear engine" compartment. The by-product is H2O, i.e. water in the form of water vapor. The heat generated during the generation of electricity is used to heat the driver's and passengers' cabin through a special heat exchanger.

Thanks to the combination of the ultra-light modular construction of the body and globally unique storage of hydrogen tanks, the bus achieves a record low hydrogen consumption - only 3.2 kg/100 km and a total range of 400 km per refueling.

A total of 4 hydrogen tanks are stored in the rear, "engine" part of the bus under a pressure of 350 bars, which is different from the case of competing buses, which have hydrogen storage on the roof due to their size and capacity.

Such a solution brings several advantages to our bus - lower weight of used tanks and less stored hydrogen, faster refueling, lower center of gravity, better handling of the bus, less load on the axles and thus longer durability and service life.

Ecology is very crucial. Regular electric buses need relatively large and heavy batteries for their purpose and range, which must be frequently recharged from the mains for a long time.

The hydrogen bus from the Slovak workshop needs disproportionately smaller batteries for its operation and range, and the need to charge them daily from the electrical network is also eliminated. It thus significantly reduces its carbon footprint and overall burden on the environment.

Filling the tanks with hydrogen under ideal conditions takes less than 10 minutes. In case of emergency, the bus can still be recharged from the mains.